The RDF stamping machine can solidify the raw materials such as wood chips, straw, rice husks, bark, cloth strips, leather and garbage from agricultural and forestry processing into high-density stamping fuel through pretreatment and processing, which can not only save energy but also reduce emissions, and has good economic and social benefits.

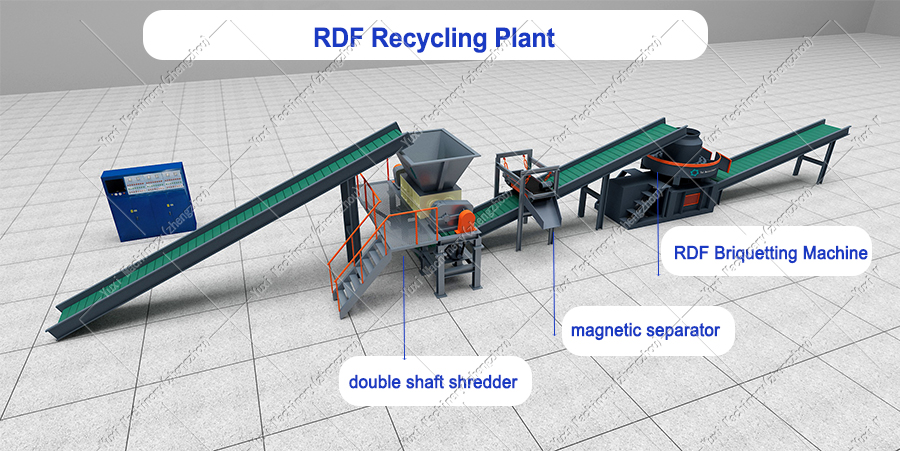

The solid form fuel, RDF for short, is made from various kinds of garbage by sorting, crushing, magnetic separation, iron removal, crushing, compression and other processes

Refuse Derived Fuel (RDF) has the characteristics of high calorific value, stable combustion, easy transportation, easy storage, low secondary pollution and low emission of dioxin substances, and is widely used in drying engineering, cement manufacturing, heating engineering and power generation engineering

Advantage of Refuse Derived Fuel (RDF) Making Machine

1. The new compression mode uses the principle of self-rotating centrifugal force to uniformly distribute the raw materials into the forming mold, which changes the phenomenon of stuffiness caused by local materials being too centered, and reduces energy consumption.

2. Multi-channel seal design prevents dust from entering the lubricated parts of the bearing.

3. The unique mold design and the interaction principle of the extrusion force between the rolling wheels, so that the molding rate is 100% under the premise of smooth discharge, and the production rate is high.

4. The operation is simple and convenient to ensure the stability of the machine's continuous work.

The price will be sent soon via email.