Application field:Mortar, yellow sand, river sand, cement plant slag, calcium carbide slag, clay, coal gangue, mixture, fly ash, gypsum

Rotary Drum Dryer Introduction

Sand dryer,also known as river sand dryer,yellow sand dryers,quartz sand dryer,is a kind of drying equipment to process large numbers of items,with reliable running,operating flexibility,adaptability,large capacity, etc.Sand drying machine is suitable for drying granular materials,especially sand,river sand,quartz sand,with excellent drying effect.

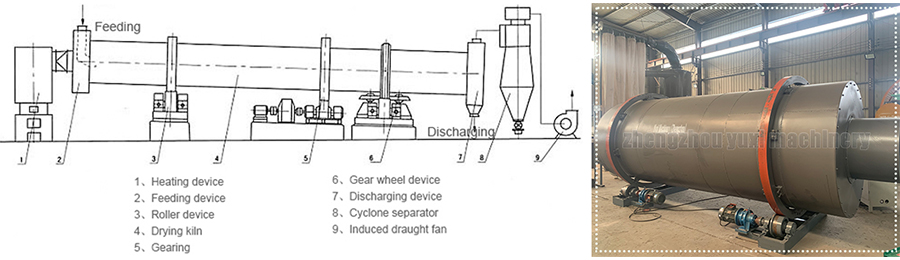

Dryer Process

1.The lignite dryer adopts a low-temperature four-stage drying process under the condition that the quality of the dried lignite remains unchanged, to evaporate the moisture of the lignite to below 13%:

2.The primary drying zone removes most of the water under high humidity at a high temperature of 400℃ to ensure that the chemical composition of lignite does not change and is not easy to burn;

3.The secondary drying zone has a room temperature of 300°C, and high-yield water removal by means of medium temperature and strong induced air to ensure that the lignite does not coke;

4.The indoor temperature of the three-stage drying zone is 120℃-210℃, and the crushing device in the drum is used to repeatedly impact and break up the materials and dry them downstream;

5.The fourth-stage drying zone is a high exhaust zone, the room temperature is 60℃-80℃, and the water is removed by the low-temperature hot air flow with negative pressure in the induced air system.

Feature of Rotary Drum Sand Dryer

1.Adopt heat resistant and wear resistant steel plate,4 times wear resistant than the general steel plate,long service time and convenient to maintain;

2.Low outlet temperature is good for keeping long service life;

3.Electric consumption reduce 60%;sand dryer

4.Adopt roller rotation,without large and small gear;

5.Hot air stove can support fluidized bed furnace,spray stove, hands burned furnace,applied to below 20mm materials such as lump material,granule and power materials;

The price will be sent soon via email.